| Availability: | |

|---|---|

| Quantity: | |

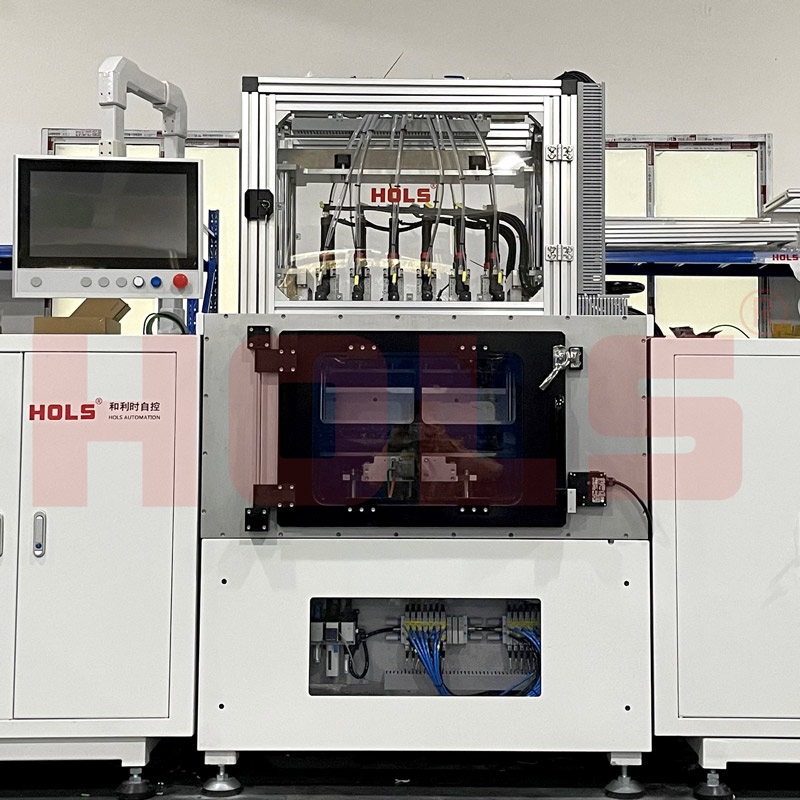

To meet the demands of potting complex components and enhance product quality, Hols developed a Vacuum Potting System utilizing a three-stage vacuum chamber for potting processes. This design ensures the core potting stages remain continuously under vacuum condition, significantly reducing cycle time (by eliminating repeated vacuum pumping/venting) and boosting production capacity, making it a cost-effective solution for high-volume manufacturing. The system is specifically optimized for fast and precise potting of small to medium-sized components.

Customizable Potting Parameters

High Precision & Intelligent

| Vacuum pumping rate | >100m3/h |

Glue dispensing speed | 0.5-10g/s |

Mixing ratio | <+-3% |

Dispensing accuracy | ≤+-2% |

| Ultimate vacuum | 5mbar |

HOLS Vacuum Potting System were designed for cost-effective batch production at the highest levels of quality. All VDS systems feature a dispensing unit for 1C or 2C potting media, depending on your needs.

To meet many requirement, various cost-effective models are therefore available both as standalone systems or for integration in a production line.

Inline Automated Weighing

Effortless, rapid automation. Enjoy superior vacuum dispensing reliability and fewer rejects from consistent quality. Inline needle and weighing control replaces tedious off-cell weighing, keeping production running seamlessly.

Precision-engineered software

The Universal Visualization software offers a powerful user interface tailored to the application for all cells, vacuum dispensing systems and Process Module. The user always has an overview of the relevant data for all processes as well as associated monitoring, maintenance and analysis tasks.

Typical applications

Potting

Insulation

Conformal coating

Potting of coil products and transformers

LED potting

The vacuum potting system process prevents residual air bubbles in the coils of transformers, batteries, motors and other components, ensuring their safe and reliable operation. It avoids component malfunctions or complete failures caused by bubble formation during potting.